Civil Engineering

Monday, October 22, 2012

Types of Weirs

Waterworks was built across the river to the completeness or shunt, and are made to raise the water level with a fixed threshold so that the river water can be tapped and fed by gravity to the irrigation network. Excess water is transferred to downstream waterfall with a swimming eject in order to reduce energy.

There are 2 types or types of fixed weir sill structure of the shape are:

Fixed threshold of the straight edge to the right edge of the river means that as the threshold is a straight line connecting the two points by the river.

Threshold fixed winding like a sawtooth. This type is required when the length threshold is insufficient and usually to wide river with a small but substantial water flow. So by using this type will be obtained length threshold larger main, so we will get a large discharge capacity of devolution. Given the physical form and character hydrolysis threshold, it is advisable weir type of chainsaw is used on the channel.

In terms applied in the river must meet the following requirements:

Debit relatively stable

Do not take the form of material floating tree trunks

The effectiveness of the weir length is limited to water depths chainsaw certain.

Vertical Motion weir

This weir weir consists of a body with a low fixed threshold is equipped with doors that can be moved vertically and radially. This type has a double function, which regulate water level in relation to the dam upstream flood water levels and elevating the river water level to do with tapping water for various purposes. Field operations carried out by opening the door all at great flood or partially open door at medium and small floods. The door is fully closed at normal time, which is for the benefit of tapping the water. Weir type of motion is only distinguished from the form of doors, among others:

Sliding doors or sliding, widely used for the width and height of the openings are small and medium. Pursued the door not too heavy because it would require a larger lift equipment and expensive. Should the door fairly light but has a high stiffness that is not easily removed when shaking the dynamic force of water flow.

Radial doors, have curved doors (arc) with the arm joints door embedded in the wing walls or pillars. Construction like this is so that leaves the door lighter to removed using a cable or chain. Homing to the door can also be done with a hydraulic push and pull mechanical equipment that is embedded in the wing walls or pillars.

Rubber dam (weir Horizontal Motion)

Rubber dam has two main parts, namely:

The body is made of rubber dam

Shaped concrete foundation slab concrete as a rubber tube holder and include a control room with some equipment (machines) to control expands and mengempisnya rubber tube.

This dam serves raise water levels by body swell dam and lower the water by means shrunken. Weir body made of rubber tubes can be filled with air or water. The process of filling the air or water from the air or the water pump is equipped with a control instrument air or water (manometer).

Weir Bottom Sieve

This form of the weir spillway weir equipped with fishing line and filter. This weir water passed through the filter to make the water tank in the form of fishing line across the river and the water flow to the river to take to the irrigation network.

Field operations performed by allowing sediment and rock jumped over the weir, the water was expected to enter the fishing line. High sediment deposited on the sand catcher channels that periodically washed into a river again.

Dam construction

Barricade is a building of water with complete built across a river or a shunt that deliberately to raise the water level or to get high jump.

Classification Weir:

A. Barricade by function divided into three:

* weir tapper

* Weir divider flood

* Retaining dam pairs

B. Weir structure:

* fixed weir

* weir motion

* weir combination

* Weir flower deflated

* Bottom intake weir

Building the physical infrastructure of the water is needed in the management of water resources.

The building is part of the spillway chainsaw waterworks, such as dam or spillway dam that serves to pass the river flow is controlled, the layout of the building is toothed like saws to increase the transfer capacity by extending the effective width of spillway.

Weir type saws are fixed weir spillway layout lighthouse resembles a sawtooth width to obtain a longer effective spillway.

There are some parts in the weir

* Body building weirs

* Intake building

* Rinse building

* building Supplies

Mercu weir dam is the top of the body where the flow of hicks can overflow to downstream. Its function as a determinant of minimum water level.

Forms lighthouse fixed weir:

Mercu round with one or two fingers to rounding

Mercu ogee type, SAF

Mercu width threshold

Lighthouse weir shape commonly used in Indonesia, which form rounded summit. This is because:

simple shape

More resistant to impact rock gelundung

Resistant to scratching or abrasion

High Mercu Weir

High lighthouse weir (p), which is the height between the floor elevation hillbilly / hick weir in the river bottom and summit elevation.

In determining the height of the lighthouse weir should consider the:

The need for obtaining discharge tapping and high press

High-energy needs flushing

High water inundation will occur

Perfection flow on the weir etc.

High lighthouse weir is recommended no more than 4.00 meters and a minimum of 0.5 H

Long Mercu Weir

Long lighthouse dam or weir is also called the span width, the distance between the two walls of the base of the weir (abutment), including the width of the building and its pillars rinse.

building intake

Intake building is a building that serves as the weir stream tapping, to regulate the importation of water and sediment.

Consists of floor / baseline, doors, flood walls, the placement of the door pillars, saqmpah strainer, bridge waitress, raumah doors, and other fixtures.

Supplementary Planning Building

Complement the building is a building that is created as a way of supporting irrigation. There's several buildings complement of which is building a cross. Building cross consists of several building types include:

1. Culverts

Culverts in the form of closed channels, the transition at the entrance and exit. Culverts will follow the slope of the line as possible. Culverts serve as an open channel for the building did not sink. Culverts full flow when the outlet if the water in the sink or higher and upstream culvert length. Loss of high-energy total for culvert drowning is the number of missing at the entrance, friction losses plus loss on corners sewer.

2. building Falls

Building falls can be combined with other buildings such as cribs, culverts and bridges to reduce overall costs.

3. chamfer

Flum is a sectional gutters or artificial channel in which water flows with a free surface, which is across the basin, canal, river, road or along the hillside. This building can be supported by pillars or other construction. Flem and gutters or steel and concrete used to carry a small discharge. For ducts greater use of concrete or steel gutters. Gutters that come with the transition in and out. It may take protection against scour at close distances downstream of the building, it depends on the speed and soil properties. Depending on the height loss of available energy and operational cost, Chambers cuts planned by the same broad-sectional area channel, only its dimensions as small as possible. Sometimes the gutters planned building small spillway to regulate water levels and discharge at the downstream chamfer. The building can be made of concrete or steel pipe.

4. Siphon

Siphon used to drain water passing under the road, through the river or in the exhaust duct. Flow in Siphon follow the principles of flow in the channel is closed. Between channels and Siphon on income and expenditure required matching transition. Loss of high energy Siphon covers loss due to friction, and loss on Siphon twists and water loss on the transition in and out. Siphon order to function properly, the building should not be entered into the air. Siphon mouth should be below the water level upstream and mouth Siphon in upstream and downstream order made streamlines. The depth of water above the top of Siphon (water seal) and the surface of the water depends on the slope and size Siphon. Siphon can be made of steel or reinforced concrete. Siphon should be used only to carry the flow channel or channels cut across where the exhaust can not be used culverts, bridges or gutters.

5. got Tilt

In the rugged terrain in which high-energy big difference must be addressed in a short distance and tertiary channel follows the slope of the terrain, sloping gutter will be required. Got siring consists of the entry, the transition, and a normal part of me grim.

6. road Inspection

Layout also includes tertiary road planning and road inspection farmers. Operation and maintenance of channels and tertiary buildings in need of inspection road along the irrigation canal to get to the box located at the tip / downstream. Because the vehicle is in use is a bicycle or motorcycle, then the width of the inspection is taken approximately 1.5 to 2.0 m. The road inspection for tertiary canal built with thick gravel base layer and 0.20 m in order to be strong enough. Best gravel for road construction material is selected from natural alluvial river that flows in the project area. The road inspection for tertiary channels can also be constructed with a base layer of gravel and / or Class B Aggregate foundation layer thickness of 0:20 m so strong. The stones that are too large loaf or ugly graded gravel should be avoided. In flat areas or swamps high street should be taken from 0.3 to 0.5 m above the surrounding ground.

Sunday, January 8, 2012

How To Calculate Concrete Method B.O.W

Koef B.O.W based materials:

Cement = 0.76

Sand = 0675

Gravel = 0.52

This means that in 1 m3 of gravel consists of pebbles m3 + 00:52 12:48 airspaces

Semen Bj = 1250 Kg

1 zak = 50 kg

concrete mixer concrete method to calculate BOW

=====> 1 m3 of concrete 1: 2: 3 so the mixture = 1 * 0.76 = .76 m3

2 m3 sand mortar finished --------> = 2 * 0675 = 1.35 m3

3 m3 kerikir -------> so mortar = 3 * 12:52 = 1.56 m3

==========================================

Material ---- produces 6 m3 = 3.67 m3 concrete

1 m3 of concrete = 1: 2: 3 ===> needed materials ...

-------------------------

Cement = 1.3.67 * 1 m3 = 0.2725 m3 = 340.5995 kg = 6812 zak

Sand = 1.3.67 * 2 m3 = 0.5449 m3

Gravel = 1.3.67 * 3 m3 = 0.8174 m3

=====> 1 m3 of concrete 1: 3: 5 to be slurry = 1 * 0.76 = .76 m3

3 m3 sand --------> so mortar = 3 * 0675 = 2025 m3

5 m3 kerikir -------> so mortar = 5 * 0:52 = 2.6 m3

========================================

9 m3 of material ---- produces concrete = 5385 m3

1 m3 of concrete = 1: 3: 5 ===> needed materials ...

-------------------------

Cement = 1/5.385 * 1 m3 = 0.1857 m3 = 232.1263 kg = 4.6425 zak

Sand = 1/5.385 * 3 m3 = 0.5571 m3

Gravel = 1/5.385 * 5 m3 = 0.9285 m3

=====> 1 m3 mortar plaster / mortar 1: 5 to be slurry = 1 * 0.76 = .76 m3

5 m3 sand mortar finished --------> = 5 * 0675 = 3375 m3

================================================

6 m3 of material - resulting slurry mortar = 0.76 + 3,375 = 4,135 m3

1 m3 of slurry mortar = 1: 5 ===> needed materials ...

------------------------

Cement = 1/4.135 * 1 m3 = 0.2418 m3 = 302.2975 kg = 6.0459 zak

Sand = 1/4.135 * 5 m3 = 1.2092 m3

Cement = 0.76

Sand = 0675

Gravel = 0.52

This means that in 1 m3 of gravel consists of pebbles m3 + 00:52 12:48 airspaces

Semen Bj = 1250 Kg

1 zak = 50 kg

concrete mixer concrete method to calculate BOW

=====> 1 m3 of concrete 1: 2: 3 so the mixture = 1 * 0.76 = .76 m3

2 m3 sand mortar finished --------> = 2 * 0675 = 1.35 m3

3 m3 kerikir -------> so mortar = 3 * 12:52 = 1.56 m3

==========================================

Material ---- produces 6 m3 = 3.67 m3 concrete

1 m3 of concrete = 1: 2: 3 ===> needed materials ...

-------------------------

Cement = 1.3.67 * 1 m3 = 0.2725 m3 = 340.5995 kg = 6812 zak

Sand = 1.3.67 * 2 m3 = 0.5449 m3

Gravel = 1.3.67 * 3 m3 = 0.8174 m3

=====> 1 m3 of concrete 1: 3: 5 to be slurry = 1 * 0.76 = .76 m3

3 m3 sand --------> so mortar = 3 * 0675 = 2025 m3

5 m3 kerikir -------> so mortar = 5 * 0:52 = 2.6 m3

========================================

9 m3 of material ---- produces concrete = 5385 m3

1 m3 of concrete = 1: 3: 5 ===> needed materials ...

-------------------------

Cement = 1/5.385 * 1 m3 = 0.1857 m3 = 232.1263 kg = 4.6425 zak

Sand = 1/5.385 * 3 m3 = 0.5571 m3

Gravel = 1/5.385 * 5 m3 = 0.9285 m3

=====> 1 m3 mortar plaster / mortar 1: 5 to be slurry = 1 * 0.76 = .76 m3

5 m3 sand mortar finished --------> = 5 * 0675 = 3375 m3

================================================

6 m3 of material - resulting slurry mortar = 0.76 + 3,375 = 4,135 m3

1 m3 of slurry mortar = 1: 5 ===> needed materials ...

------------------------

Cement = 1/4.135 * 1 m3 = 0.2418 m3 = 302.2975 kg = 6.0459 zak

Sand = 1/4.135 * 5 m3 = 1.2092 m3

EXPENSES calculated in BRIDGE PLAN

In general, the burden - the burden is calculated in the planning of the bridge is divided into two primary loads and secondary loads. The primary burden is a major burden in planning setipa stress calculations for the bridge, while the secondary load is the load while the resulting voltage - the voltage is relatively smaller than the primary voltage due to load and usually depends on the landscape, materials, construction systems, bridge type and local circumstances.

Primary burden of the bridge include dead loads, live loads and shock loads.

1. Dead load

Dead load is all cargo originating from its own weight of the bridge or bridge sections are reviewed, including any additional element is fixed that is considered one unit with a bridge. In determining the dead load weight of the volume should be used for building materials.

examples of dead load on the bridge: the weight of concrete, asphalt weight, the weight of steel, heavy masonry, stucco, etc. weight.

2. Living Expenses

Which includes the live load is the load that comes from moving vehicles, heavy traffic and / or pedestrians who considered working on the bridge. Based PPPJJR-1987, pages 5-7, the burden of living under review consists of:

a. Expenses "T" (Burden floor vehicles)

Expenses "T" is a load trucks that have a dual wheel load (Load Dual Wheel) by 10 tons, which works on the entire width of the bridge for vehicular traffic dingunakan.

b. Load "D" (Line traffic)

Load "D" is the arrangement of the load on each lane of traffic which consists of the load line "P" tons per lane of traffic (P = 12 tons) and the load evenly split "q" tons per meter length per lane as follows:

q = 2.2 t / m for L <30 m.

q = 2.2 t / m - {(1,1 / 60) x (L - 30)} t / m to 30 m

q = 1.1 {1 + (30 / L)} for L> 60 m.

Terms of use load "D" in the transverse direction of the bridge as follows:

§ To bridge the width of the vehicle floor <5.50 m, the burden of "D" is fully (100%) should be charged on the entire bridge.

§ To bridge the width of the vehicle floor> 5.50 m, the burden of "D" is fully (100%) charged to the line width of 5.50 m while the width of the remaining encumbered only half load "D" (50%).

examples of live load on the bridge: the burden of passing vehicles, loads of people walking, etc.

3. Shock load

According to Anonymous (1987:10) shock loads into account the influence of the vibrations of other dynamic effects., Stresses due to the load line (P) must be multiplied by the coefficient of shock. While the load evenly split (q) and the concentrated load (T) is multiplied by the coefficient of shock. The amount of shock coefficient is determined by the formula:

k = 1 + ((20 / (50 + L))

While the Secondary Expenses consist of wind load, brake force, and force due to temperature differences.

1. Wind load

Effect of pressure of work in the horizontal wind at 100 kg/cm2. In calculating the total area of the bridge on each side of the vast number of parts used jembata on each side used the following provisions:

* For a full walled jmbatan taken as 100% on the broad side of the bridge

* To bridge order was taken by 30% against the broad side of the bridge.

2. Brake force load

This style works in the lengthwise direction of the bridge, due to brake and traction force are reviewed for both the traffic department. this effect is taken into account the influence of worth to the brake force at 5% of the charge coefficient D without shock that meets all existing traffic lane in one direction.

3. Due to the style of Temperature Difference

The temperature difference should be determined in accordance with local circumstances. Of C is assumed for the steel and concrete 10. Special review on the incidence of stresses due to temperature differences that exist between parts of the bridge with different materials.

4. Earthquake load

for bridge construction in areas affected by the earthquake, the earthquake load is also taken into account in the planning of the bridge structure

5. Wind loads

wind load is calculated on the bridge construction area that must withstand wind loads.

Primary burden of the bridge include dead loads, live loads and shock loads.

1. Dead load

Dead load is all cargo originating from its own weight of the bridge or bridge sections are reviewed, including any additional element is fixed that is considered one unit with a bridge. In determining the dead load weight of the volume should be used for building materials.

examples of dead load on the bridge: the weight of concrete, asphalt weight, the weight of steel, heavy masonry, stucco, etc. weight.

2. Living Expenses

Which includes the live load is the load that comes from moving vehicles, heavy traffic and / or pedestrians who considered working on the bridge. Based PPPJJR-1987, pages 5-7, the burden of living under review consists of:

a. Expenses "T" (Burden floor vehicles)

Expenses "T" is a load trucks that have a dual wheel load (Load Dual Wheel) by 10 tons, which works on the entire width of the bridge for vehicular traffic dingunakan.

b. Load "D" (Line traffic)

Load "D" is the arrangement of the load on each lane of traffic which consists of the load line "P" tons per lane of traffic (P = 12 tons) and the load evenly split "q" tons per meter length per lane as follows:

q = 2.2 t / m for L <30 m.

q = 2.2 t / m - {(1,1 / 60) x (L - 30)} t / m to 30 m

q = 1.1 {1 + (30 / L)} for L> 60 m.

Terms of use load "D" in the transverse direction of the bridge as follows:

§ To bridge the width of the vehicle floor <5.50 m, the burden of "D" is fully (100%) should be charged on the entire bridge.

§ To bridge the width of the vehicle floor> 5.50 m, the burden of "D" is fully (100%) charged to the line width of 5.50 m while the width of the remaining encumbered only half load "D" (50%).

examples of live load on the bridge: the burden of passing vehicles, loads of people walking, etc.

3. Shock load

According to Anonymous (1987:10) shock loads into account the influence of the vibrations of other dynamic effects., Stresses due to the load line (P) must be multiplied by the coefficient of shock. While the load evenly split (q) and the concentrated load (T) is multiplied by the coefficient of shock. The amount of shock coefficient is determined by the formula:

k = 1 + ((20 / (50 + L))

While the Secondary Expenses consist of wind load, brake force, and force due to temperature differences.

1. Wind load

Effect of pressure of work in the horizontal wind at 100 kg/cm2. In calculating the total area of the bridge on each side of the vast number of parts used jembata on each side used the following provisions:

* For a full walled jmbatan taken as 100% on the broad side of the bridge

* To bridge order was taken by 30% against the broad side of the bridge.

2. Brake force load

This style works in the lengthwise direction of the bridge, due to brake and traction force are reviewed for both the traffic department. this effect is taken into account the influence of worth to the brake force at 5% of the charge coefficient D without shock that meets all existing traffic lane in one direction.

3. Due to the style of Temperature Difference

The temperature difference should be determined in accordance with local circumstances. Of C is assumed for the steel and concrete 10. Special review on the incidence of stresses due to temperature differences that exist between parts of the bridge with different materials.

4. Earthquake load

for bridge construction in areas affected by the earthquake, the earthquake load is also taken into account in the planning of the bridge structure

5. Wind loads

wind load is calculated on the bridge construction area that must withstand wind loads.

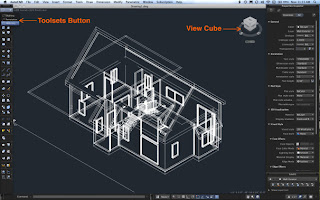

AutoCAD for Mac

AutoCAD, the industry-standard Computer Aided Design (CAD) application from Autodesk, is back on the Mac after an 18-year hiatus. This is lovely news for lots of Mac fans in the architecture, engineering, and design professions who have been reluctant to give up their MacBook Pros and iMacs for the sake of a single application, despite its status as a important part of their workflow. With the new Mac version of AutoCAD for freeform 2D and 3D design and drafting, Mac users no longer need to make use of Boot Camp or Parallels or suffer a PC on the same table with their Mac.

In lieu of offering the ribbon-based interface of the Windows version, Autodesk has has selected to place more AutoCAD functions in the pulldown menus. Floating gizmo palettes also include most of the same tools as the menus, while the interface will look familiar to users of other Mac CAD applications. Autodesk has also taken advantage of multi-touch trackpad gestures (& offers similar moves on Apple's Magic Mouse () For example, two-finger swipes scroll up or down, pinching can zoom in or out, & a shift and two-finger swipe can rotate around a 3D model. Cover Flow navigation lets you flip through your designs. Nice

AutoCAD 2011 for the Mac is not a port from Windows. , Autodesk has programmed this version for the Mac from the ground up with a conscious work to take advantage of the Mac OS X interface.

While AutoCAD is a complex and powerful application, the technique requirements are higher than much of the competition on the Mac (such as Vectorworks (), TurboCAD (), and Ashlar-Vellum), beginning with a maximum of 3GB of RAM and higher screen resolution (1280 x 800 pixels). The program works with only with more recent Mac hardware such as Mac Pro (early 2009), MacBook Pro (mid-2009), and iMac (early 2008). To be fair, you'd require to make use of a high resolution monitor with a CAD program anyway, given the quantity and level of graphic detail you are usually working with. But, you are less likely to be disappointed with AutoCAD's performance in case you bought your Mac in the last couple of yearsWhile AutoCAD is a complex and powerful application, the technique requirements are higher than much of the competition on the Mac (such as Vectorworks (), TurboCAD (), and Ashlar-Vellum), beginning with a maximum of 3GB of RAM and higher screen resolution (1280 x 800 pixels). The program works with only with more recent Mac hardware such as Mac Pro (early 2009), MacBook Pro (mid-2009), and iMac (early 2008). To be fair, you'd require to make use of a high resolution monitor with a CAD program anyway, given the quantity and level of graphic detail you are usually working with. But, you are less likely to be disappointed with AutoCAD's performance in case you bought your Mac in the last couple of years.

When you first launch AutoCAD 2011, you will be introduced with the drawing canvas or Modelspace, the window where you will build your drawing or model. The menus are extensive, and the gizmo and information palettes are arranged to the left and right of the canvas.

of the first things you will notice is that the default background in AutoCAD is black or slate-colored with the lines and objects you draw in white (or bright colors). This differs from most Mac CAD or graphic design applications, which usually have a white background with black and color drawing elements on top. You can change the background color in the preferences and, in fact, much of the interface can be altered to fit your own tastes, including which tools show up in the palettes and where the palettes can be found on screen.

One interface element Autodesk brought over from the Windows version is the ViewCube, a useful graphical navigation element for controlling 3D views. It lets you rotate your drawing & model, or jump to standard 3D views & orientations with a single-click. The ViewCube rotates as you click on it, giving you a visual representation of your drawing at various angles. Moving around a 3D model can be disorienting, & the ViewCube does a lovely job of letting you know whether you are looking from above, below, or at some oblique angle.

Another uniquely AutoCAD interface element is the Command Line window. This has been an AutoCAD mainstay for lots of years. At first it looks like some DOS operating process throwback, but it is actually a very useful window because it displays in text format everything that is going on while you re drawing, line-by-line, command-by-command. Interestingly, it can operate both ways: you can enter text commands in to the window & control your drawing from the command line while maximizing the use of the keyboard & minimizing use of the mouse & menus. While overall that method of operation is not very Mac-like, in case you have been using the Windows version of AutoCAD for a very long time, this feature will be welcome.

From the Mac point of view, though, my largest complaint about the interface is that the method of drawing objects often includes more clicks than necessary, & can need the use of the keyboard.

For instance, drawing a simple line is not as simple as choosing the line gizmo and then clicking and dragging to generate the line. In AutoCAD, to finish the system of drawing the line, you require to hit another key such as Escape or Enter, or the Space Bar after the second click. Otherwise, you will keep adding more lines. Then, in the event you require to draw another line elsewhere, you require to pick the line gizmo again. No doubt, this is something you can get used to, but Id not must click so much.

While plenty of CAD programs can import & export DWG files, these translations sometimes need cleanup. Not having to worry about cleanup or whether your exported DWG files will open correctly is actual advantage of AutoCAD for Mac over other Mac CAD programs. I opened numerous DWG files received from Windows consultants I work with & AutoCAD for Mac opened most of them seamlessly. However, I did run in to a tiny number of drawings that necessary parts not obtainable for the Mac, such as some (but not all) ObjectARX parts my civil engineer makes use of. Some of these parts, made by third-party vendors, are widely used & personalize & extend AutoCAD. I hope that the developers of such parts update them for use on the Mac.

One of the reasons plenty of architecture firms use AutoCAD is the popularity of its file format. The DWG format native to AutoCAD is often used for collaborative work across a broad range of professions such as consultants, architects, and engineers.

This brings up the subject of add-ons for AutoCAD. thing that makes AutoCAD for Windows such a dominant product are all of the third-party extensions obtainable. In the Windows version, there's add-ons & extensions obtainable for any profession or specialty, & there's thousands of tools & scripts that you can add to AutoCAD that provide even more capabilities than are included in the basic application. A number of the add-ons are already obtainable for the Mac, but today, most are not. For example, I ran in to some missing extensions while trying to import AutoCAD files from a civil engineer I work with. Autodesk says it is working on having more extensions obtainable for later releases of the Mac program, & will be making the development of add-ons feasible on the Mac.

Like PDF, there's dozens of features in the Windows version that are not included in the Mac version. A quantity of them are important features such as Plot Style Configuration, Plot to File, or the Reference Manager.

One glaring feature missing from AutoCAD 2011 is support for importing and exporting PDF files. In the current version, there is no export or print-to-PDF feature from within AutoCAD. Using the print-to-PDF option in the standard Mac print dialog box gives poor results compared to other CAD programs with built-in PDF support (including AutoCAD for Windows). There is also no way to import a PDF file in to your drawing, another feature supported in the Windows version of AutoCAD, but not on the Mac.

With this first comeback version of AutoCAD, Autodesk appears to be applying the 80/20 rule for its Mac users, providing the 80 percent of features and tools that are used the most. I don't have a conceptual issue with that approach. It seems sane for such a immense program to implement the most important parts first and then fill inOn a positive note, Autodesk has a free iPhone/iPad app available in the iTunes store that lets you share and view AutoCAD files in the field. You may even do some light editing of the files right on your iPhone or iPad, including drawing new objects, moving, rotating, and annotating.

Tuesday, December 27, 2011

Low Cost Steel Detailing and Structural Steel Design Services

Outsourcing Steel Detailing firm is a leading steel design service provider company specializing in steel structure designing & steel detailing services. They offer custom-tailored 2D & 3D Steel Designing & Detailing solutions to help you turn today's challenges in to competitive advantage. They use application like AutoCAD, AutoSketch, Revit, Tekla, etc & web-based collaborating tools to provide you the benefits of low operating cost, superior services & efficient delivery schedule.

Steel structures are widely used in steel building designs & construction of residential steel building design. Structural Steel detailing is useful for all kind of steel structures ranging from residential buildings to massive commercial buildings. Steel structures can be designed or planned basically with less hard work & provides advantages like sturdiness, durability & portability. Structural steel services include designing dimensions & detailing of various Post-tensioned, Precast concrete detailing, Pre-stressed & Composite steel structures in accordance with industry standards & codes.

They have a massive pool of highly qualified steel detailers & structural steel engineers producing correct drawings of each structural element, their placements, connections between them & exact dimensions. This involves detailing of steel staircases, beams, plates, columns, bar joists, stack, decking/grating, etc. Our methodology is well defined & technique & result oriented. They put our best hard work to establish fruitful business partnership with our clients by ensuring exact, correct, high quality steel detailing services within the budget & on time.

They provide structural steel designs for industrial structures such as:

Steel buildings

Residential/Commercial buildings

Residential Steel framing

Warehouses

Sheds/Shelters/Roofs

Office blocks

Support structures

Floor systems/Mezzanines,

Miscellaneous Steel structures

Subscribe to:

Comments (Atom)